Phoenix

Return

Capsule

European origin with global ambition. Research in life sciences, specifically for monoclonal antibodies, stem cells, organoids, and protein crystallization, offers unique opportunities in Space. Launching experiments has become simpler and cheaper, but returning to Earth remains a challenge due to high costs, long lead times, and issues with repeatability and reliability.

The solution is to provide a return service tailored specifically for life sciences, which is highly affordable, reliable, with regular flights and short lead times.

- Payload capacity: 100 kg

- Flight duration: selectable up to 3 months,

for longer missions please contact us. - Late Access for sample loading possibilities.

- Status connection during flight (TMTC)

- Data: UART, I2C, SPI, CAN, SpaceWire , MIL1553, SLink

- Power: 100 W, for more please contact us.

- Form factors: ISS Middeck Locker, 1U, 2U, 3U formats

(other form factors on request)

- Pressurized payload bay:

Temperature setpoint selectable from 20°C to 37°C,

for other temperatures please contact us. - Vacuum payload bay:

Structural interface temperature setpoint selectable

- Transport to launch site from customer selected general aviation airport.

- Payload integration at launch site.

- Payload retrieval on return from space.

- Payload return to customer selected general aviation airport.

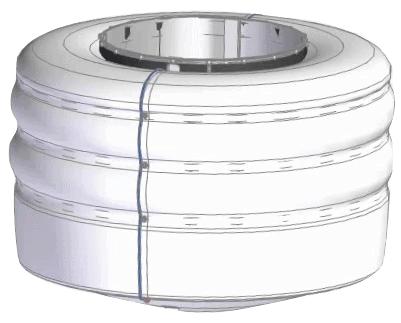

INFLATABLE

ATMOSPHERIC

DECELERATOR

We offer an unmatched scalable solution to bring back cargo from space. From shoebox-sized scientific experiments to the largest rocket stages, our approach is tailored to each individual object and our method is highly cost efficient.

We develop Inflatable Atmospheric Decelerators (IADs), which function both as a heat shield and as a high-velocity parachute, protecting their precious cargo during re-entry into the atmosphere.

Unlike the propulsive landing method which is becoming the industry standard for returning first stages now, our technology uses zero fuel. This is not only better for the environment, but it also makes our solution more lightweight. In fact, IADs are so lightweight that they can be used to recover and reuse complete micro launchers. They can also be retrofitted to make almost any rocket stage, space module or satellite returnable and reusable.

- Light weight, strong and high temperature resistant.

- Reusable radiatively cooled Ceramic Matrix Composite

(CMC) heat shield. - Deceleration capability: From 7800 m/s orbital speed

all the way down to Earth in one system.

Atmos Facility

Lichtenau (Baden)

Our international team builds European high-end technology at Lichtenau, located on the Franco-German border. The proximity to Karlsruhe/Baden-Baden Airport means that we are well placed in terms of air, sea, rail and road logistics.

Our site is also close to world-class academic institutions, including the University of Stuttgart, the International Space University in Strasbourg and Karlsruhe Institute of Technology. The beautiful natural setting of the nearby Black Forest National Park and the Rhine River offers plenty of opportunities for rest and recreation and is a constant reminder of why we do what we do.